SmartFactory

Mondrian AI provides automated QC monitoring and unattended product management services by incorporating AI on the production line.Mondrian AI uses big dan AI to automate the manufacturing process, helping you manufacture the product at lower cost and less time. Data is collected and analyzed in real-time by non-intrusive image sensors installed on the factory facilities so that the situation in the factory is clearly visible and can be analyzed and controlled according to their purpose.

Emergency

alarm

If a problem arises during the production, the system will notify the person in charge by sending SMS containing information about the event type, time of occurrence and location.

Optical Character Recognition(OCR)

Based on the image information, the system reads the numerical values and converts the values appearing on the analog instrument panel into digital information.

Intelligent

defect detection

The images collected are fed as training data into the AI system and once the model is generated, it will be able to automatically detect abnormalities such as material damage, breakage, different product identification, and other defect.

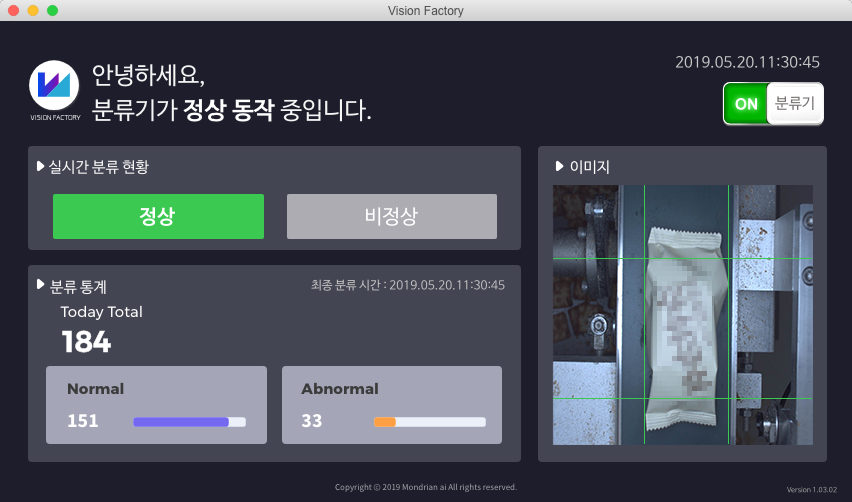

Monitoring

system

Provides a comprehensive factory control system under a single dashboard that displays the status of data collected and the analysis and statistical results from the data.

Why Mondrian AI

Challenges

The manufacturing companies can incrase the competitiveness by applying new technologies such as automation and smart manufacturing management systems. Due to rising labor costs each year, product management costs are rising while companies must maintain excellent quality control. It is not easy to detect a QC problem before it occurs. Furthermore, if immediate response is not taken after a problem occurs, it will cause fatal damage to the entire plant.

Opportunity

Intelligent process monitoring has become possible through the use of image sensors fitted to the purpose without the need for physical modifications to existing processes. Using one AI model derived through big data process, automated classification on the product is performed and thus enabling real-time quality management and control.

Benefits of

Scenario

Mondrian AI provides intelligent identification solutions that can be universally used via camera sensors without the need to modify the existing processes. Reduce costs and time, and improve quality with a simple, user-friendly interface, without the need for large numbers of repetitive, labor-intensive defect detection and quality controls.

UseCase

Digital output via image of analog meter

The analog meter reading of the existing process is acquired by video and converted to a format that can be used in the computer system. In addition, the camera sensor automatically identifies characters such as incorrect printing of product information or expiration dates to detect errors. Intelligent model automates the collection of information from various types of equipment in the process without having to manually record each time.

AI-based detection for defects on product packages

We provided a system that can determine whether a product is defective or not in a production line that churns 3 items/second by using intelligent cameras. This allowed the workers to skip the unnecessary process of manual defect inspection and classification, which helped reduce consumer complaints and improved the overal QC service level.

Contact Sales

We will help answer your inquiry regarding technology support, information sharing, solution and other smart factory-related inquiries.